Pedal Power: Difference between revisions

Ted Moallem (talk | contribs) No edit summary |

Ted Moallem (talk | contribs) No edit summary |

||

| Line 7: | Line 7: | ||

'''<span style="color:#ff0000;">11/ | '''<span style="color:#ff0000;">11/29/11: UPDATE IN PROGRESS</span>''' | ||

__TOC__ | __TOC__ | ||

| Line 22: | Line 24: | ||

List admin: [mailto:moallem@mit.edu?subject=OB%20PedalPower%20Documentation moallem@mit.edu] | List admin: [mailto:moallem@mit.edu?subject=OB%20PedalPower%20Documentation moallem@mit.edu] | ||

<p style="text-align: center;"></p><p style="text-align: center;">(** PLEASE DO NOT RELOCATE OR RADICALLY MODIFY THIS PAGE WITHOUT FIRST CONTACTING LIST ADMIN. KTHX **)</p> | <p style="text-align: center;"></p><p style="text-align: center;">(** PLEASE DO NOT RELOCATE OR RADICALLY MODIFY THIS PAGE WITHOUT FIRST CONTACTING LIST ADMIN. KTHX **)</p> | ||

== Parts/Materials List == | == Parts/Materials List == | ||

<p style="text-align: center;">''<span style="font-size:larger;">"A-frame" bicycle stand</span>''</p> | <p style="text-align: center;">''<span style="font-size:larger;">"A-frame" bicycle stand</span>''</p> | ||

| Line 139: | Line 140: | ||

*'''IMPORTANT''': Depending on circuit configuration, it may be necessary to connect diode and voltage regulator to <u>separate, non-contacting heat sinks</u>. (Remember, aluminum conducts electricity!) | *'''IMPORTANT''': Depending on circuit configuration, it may be necessary to connect diode and voltage regulator to <u>separate, non-contacting heat sinks</u>. (Remember, aluminum conducts electricity!) | ||

<div><br/></div> | <div><br/></div> | ||

== Construction == | == Construction == | ||

Revision as of 15:59, 29 November 2011

Pedal Power for the Occupy Movement

To support the self-sufficiency of Occupy member sites, the Pedal Power group aims to facilitate the low-cost construction and effective usage of pedal-powered electrical generators and related technologies.

The goal for this design was low cost, with most materials sourced from Home Despot and/or local hardware stores. Can be built relatively easily by anyone with access to drill press and basic tools. Circuitry includes voltage regulator ($1.50 from digikey), a few capacitors/resistors, and a diode.

11/29/11: UPDATE IN PROGRESS

Contact Info

Group email: pedalpower@mit.edu

List admin: moallem@mit.edu

(** PLEASE DO NOT RELOCATE OR RADICALLY MODIFY THIS PAGE WITHOUT FIRST CONTACTING LIST ADMIN. KTHX **)

Parts/Materials List

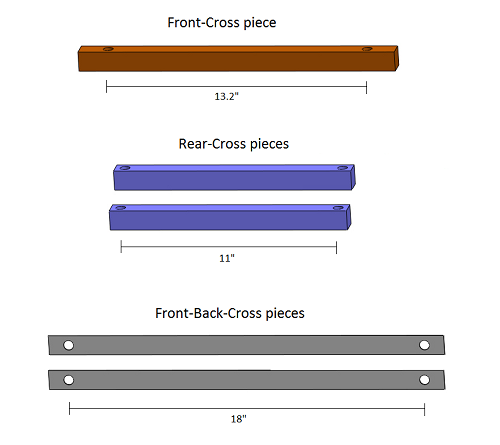

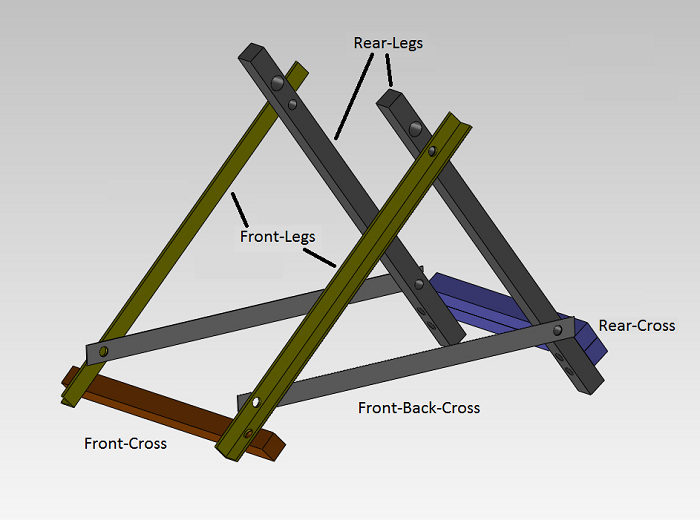

"A-frame" bicycle stand

Rear Legs:

TWO (2) x 20" lengths of 1" x 1" (cross-section) rectangular steel tubing

- e.g., http://www.homedepot.com/h_d1/N-5yc1v/R-202183567/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053

- Alternatively, can use up to 2" x 1" (cross-section) rectangular steel tubingfor added stability

Rear-Cross piece:

TWO (2) x 12" lengths of 1" x 1" rectangular steel tubing

- Alternatively, can use single piece of 2" x 1" rectangular steel tubing

Front Legs:

TWO (2) x 20" lengths of 1-inch angle steel

- e.g., http://www.homedepot.com/h_d1/N-5yc1v/R-202183502/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053

- Alternatively, can use 20" lengths of 1" x 1" rectangular steel tubing

Front-Cross piece:

ONE (1) x 16" length of 1" x 1" rectangular steel tubing

- For extra stability, lengthen FRONT-CROSS piece to between 20"-30", and add rubber feet at either end

Front-Back-Cross pieces:

TWO (2) x 20" lengths of flat steel bar

Nuts and Bolts:

- Use bolts sized 10mm to 12mm (standard sizes 3/8, 7/16, or 1/2), 'with correspondingly sized nuts, unless otherwise specified.

- Drill holes to slightly larger diameter than that of traversing bolt.

____________________

Rear-wheel (skewer) supports:

TWO (2) x5"-6" long fully-threaded bolts, size 3/4-10 (standard)

- bolt head type does not matter

- Alternatively, can use 5"-6" lengths of 3/4-10 threaded rod

FOUR (4) x 3/4-10 Hex Nuts

TWO (2) x 1/2 in. PVC Sch. 40 Pressure Slip x FIPT Female Adapter

TWO (2) x Hose clamps [OPTIONAL]

- Hose clamps are optional --- to reinforce PVC adapter cups, if desired

- e.g., http://www.homedepot.com/h_d1/N-5yc1v/R-202309385/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053

____________________

Generator and mounting assembly:

ONE (1) x 24V DC motor (100 to 350 watt)

ONE (1) x heavy-duty door hinge

ONE (1) x strong L-bracket, at least 3" long on one side

TWO (2) x mounting plates (approx. 5" x 5", either steel or thick aluminum)

ONE (1) x roller bearings (should fit motor shaft perfectly)

ONE (1) x roller: solid aluminum cylinder, 1.25" to 1.5" diameter (Note: Can alternatively use Nylon cylinder with thin aluminum pipe as sheath)

[SPECIFY BRACKETS, FASTENER HARDWARE, AND DISTAL ROLLER SUPPORT!!! ]

[INCLUDE EXAMPLE LINKS!!!]

____________________

Electronics:

ONE (1) x low-voltage schottky diode

- e.g., http://search.digikey.com/us/en/products/SR1045-TP/SR1045-TPMSCT-ND/2334476

- e.g. (alt), http://search.digikey.com/us/en/products/MBR1645G/MBR1645GOS-ND/918588

- Note: Regular diode will work, but schottky diode minimizes power loss

ONE (1) x adjustable positive voltage regulator

- e.g., 5-Amp low dropout (LDO) linear voltage regulator: http://search.digikey.com/us/en/products/LD1084V/497-3413-5-ND/669183 [LD1084V Datasheet]

- e.g. (alt), 7.5-Amp LDO linear voltage regulator: http://search.digikey.com/us/en/products/LT1083CP%23PBF/LT1083CP%23PBF-ND/888922 [LT1083 Datasheet]

- Note: Appropriate adjustment of maximum output voltage commonly requires several additional electronic components, as specified in voltage regulator datasheet. For the LD1084V regulator used below, the required components are two capacitors (both 10 uF) and two resistors (120 Ω and 1.2 kΩ)

Two (2) x aluminum heat sinks

- Can use scrap aluminum bar or thick sheeting, so long as there is a flat surface for mounting to components

- IMPORTANT: Depending on circuit configuration, it may be necessary to connect diode and voltage regulator to separate, non-contacting heat sinks. (Remember, aluminum conducts electricity!)

Construction

Basic A-frame configuration, depicted without nut/bolt fasteners.

- On one face of each rear leg piece, mark distances of 1.5" and 2.5" from bottom edge, centered along the width. Drill two through-holes, slightly larger than fastening bolt diameter.

- On perpendicular face of each rear leg piece, mark distances of 4", 16.5", and 18" from bottom edge, centered along the width.

- At 4" and 16.5" marks, drill through-holes, slightly larger than bolt diameter.

- At 18" mark, drill though-hole of approximately 0.75" diameter (to fit size 3/4-10 bolt or threaded rod).

- If using angle steel, note that hole patterns of the two front legs are mirror images of one another.

- On one face of each front leg piece, mark distance of 1.5" from bottom edge, centered along the inner-face width. Drill through-hole slightly larger than fastening bolt diameter.

- On perpendicular face of each front leg piece, mark distances of 3" and 18" from bottom edge, centered along the inner-face width. Drill through-holes slightly larger than fastening bolt diameter.